Electronic Manufacturing Services (EMS) refer to a range of services provided by companies that design, test, manufacture, distribute, and offer return/repair services for electronic components and assemblies for Original Equipment Manufacturers (OEMs). This concept is also known as Electronic Contract Manufacturing (ECM).

Distinguishing EMS, OEM, and ECM

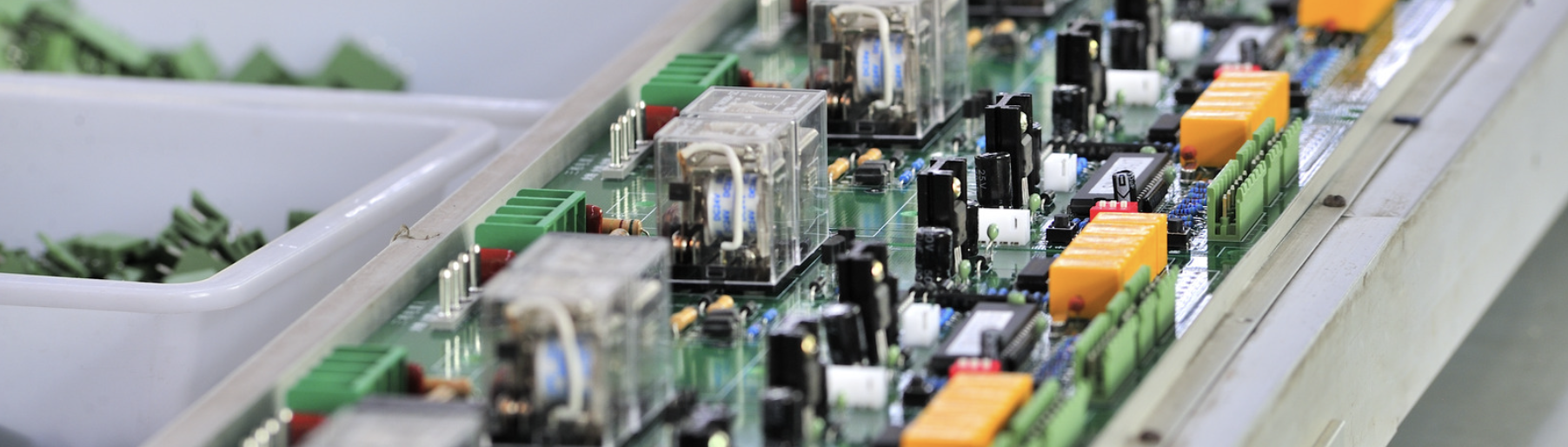

EMS (Electronic Manufacturing Services): EMS companies offer comprehensive manufacturing services, including design, assembly, and testing of electronic components and Printed Circuit Boards (PCBs). These providers often manage the entire product lifecycle, from production to after-sales support and repair services. They may also assist in supply chain management, which helps OEMs with logistics and material sourcing.

The EMS sector covers various specialized services such as:

- PCB Assembly: Including Surface Mount Technology (SMT) and Through-Hole Technology (THT) to assemble complex electronic components.

- Advanced Engineering Services: Such as PCB design for manufacturability (DFM) and testability (DFT), thermal and mechanical simulation, and expertise in RF/wireless systems and embedded electronics.

- Original Equipment Manufacturers (OEM). OEMs are the driving force behind product innovation, design, and branding. They own the intellectual property of the product and, depending on their capabilities, either manage production in-house or outsource it to EMS providers. OEMs concentrate on R&D, design, and customer-facing activities, while EMS companies handle manufacturing, assembly, and testing.

Overview of the EMS Market

The market for electronic manufacturing services was valued at over USD 584.69 billion in 2024 and is expected to exceed USD 1.42 trillion by 2037, with a compound annual growth rate (CAGR) of over 7.1% during the forecast period from 2025 to 2037.

The market for electronic manufacturing services was valued at over USD 584.69 billion in 2024 and is expected to exceed USD 1.42 trillion by 2037, with a compound annual growth rate (CAGR) of over 7.1% during the forecast period from 2025 to 2037.Trends in Outsourcing

Sector Growth

Regional Dominance

Key EMS Services

What Do Electronic Manufacturing Services Include?

- PCB & PCBA Design and Engineering

- Design for Manufacturability (DFM): Optimizing design for cost-effective, efficient mass production.

- Design for Testability (DFT): Ensuring easy testing with planned test points and diagnostics.

- Advanced Engineering Services: Simulation, analysis (thermal, mechanical, electromagnetic), RF/wireless design, embedded systems, and power electronics.

- Compliance & Certification: Meeting industry standards (FCC, CE, UL, RoHS) for safety and regulations.

- Prototyping and Pre-production: Before going into production, It's nessesary to produce prototypes and/or pre-production parts to make any necessary adjustments.

Electronic Component Sourcing

Electronic manufacturing service providers often have established relationships with a wide range of suppliers and distributors as MT Power Limited. These relationships allow them to source components efficiently and at competitive prices. They may also have access to global supply chains, which is advantageous for sourcing rare or hard-to-find components.

Electronic Manufacturing Service & Assembly Service

PCB Assembly:

PCB Assembly:

- SMT (Surface Mount Technology): Components are placed directly on the PCB surface, allowing for compact, high-density designs.

- THT (Through-Hole Technology): Components with leads are inserted into pre-drilled holes and soldered, providing durability for high-stress or high-temperature applications.

Other Assembly Services:

- Cable & Wire Harness Assembly – Organizing and connecting wires for reliability.

- Electromechanical Assembly – Integrating electronic and mechanical components.

- Prototype Assembly – Fast, small-scale production for testing and development.

Benefits of Outsourcing Electronic Manufacturing

5 Questions to Ask Your Electronics Manufacturer

-

What is your experience in manufacturing products similar to mine?

Understanding the manufacturer’s experience with your specific product category is key. It provides insight into their ability to meet your project's unique requirements. -

Can you provide detailed information about your quality control processes?

Quality control is critical in electronics manufacturing. Ask about their quality control practices, certifications (such as ISO 9001), and how they address non-conformities and defects. -

How do you manage the supply chain and sourcing of components?

Considering the global complexity of electronics supply chains, it's important to understand how the manufacturer sources components. This includes their strategies for handling component shortages and cost management. -

What are your capabilities for scalability and flexibility?

Assess their ability to adjust production levels based on demand. This is crucial for responding to market changes and meeting your production needs efficiently. -

How do you protect intellectual property and ensure confidentiality?

Ensure your intellectual property is safeguarded. Ask about their policies and measures in place to protect sensitive information.

Let’s build high-quality, high-performance products together. MT-Power Electronics Limited today to discuss how our certified EMS services can support your next project!